A team at CEA-Liten has been studying these materials with a view to optimising their use and exploring new applications. HITEC, a commercially available PCM consisting of a ternary mixture of nitrate salts and nitrate, has been classified as part of the European project FriendSHIP. HITEC has many interesting properties, being one of the only PCMs to boast all of the following characteristics: good thermal stability, high latent heat and a high volumetric heat capacity (rho.cp). It also has a melting point of 142°C — in a temperature required for many industrial processes. Likewise, the ability to use this phase-change material to stock solar energy would significantly reduce industrial carbon emissions.

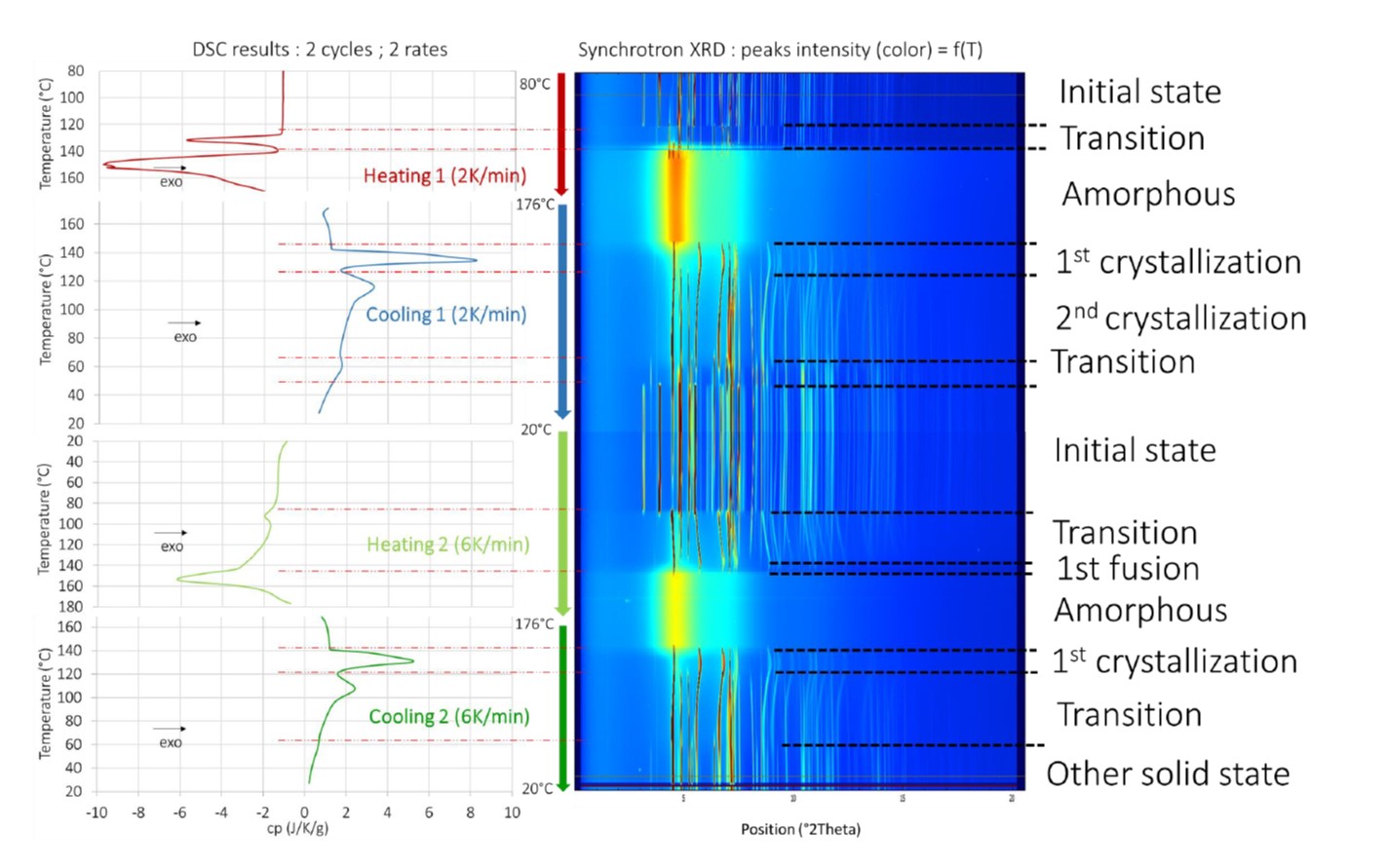

In order to understand the phase-change mechanism and assess HITEC's long-term stability, researchers at CEA-Liten have pooled together various analysis techniques on different scales. Results from calorimetry tests have shown that HITEC is non-eutectic, and several solid-solid transitions have been observed. These phase changes were identified through a Synchrotron X-ray diffraction study with several temperature ramps. This also led to the discovery of a risk of incongruent crystallisation. Efforts will continue in this area, with diffractograms being used to measure crystallisation kinetics and to determine the product's stability on a larger scale, under specific conditions.

Differential scanning calorimetry (left) and synchrotron X-ray diffraction analysis (right) of HITEC salt across two thermal cycles at heating rates of 2 K/min and 6 K/min

These results were presented during the MSE 2024 Congress in Darmstadt in late September, and were awarded the Best Poster prize in their respective category.