Amid volatile energy prices and an energy landscape in transition, making industrial processes more energy-efficient is vital to ensuring manufacturers' economic competitiveness and to overcoming the broader challenge of decarbonizing the industrial sector. For a given production volume, waste heat recovery reduces energy consumption and the associated GHG emissions and energy spend. In France alone,

heat accounts for

40% to 45% of the total energy consumed by end users. In fact, at around 750 TWh, heat far outpaces the nation's electricity consumption, which stands at around 450 TWh.

Industrial processes are responsible for

30% of total heat consumption, a third of which is wasted. Fortunately, waste heat can be captured, reused (in the same process whenever possible, mainly for energy reasons), and stored to compensate for process-related demand fluctuations.

Food manufacturing, with

heat-intensive processes like sterilization, is responsible for 30% of industrial waste heat in France, making it a prime candidate for waste heat recovery solutions. The

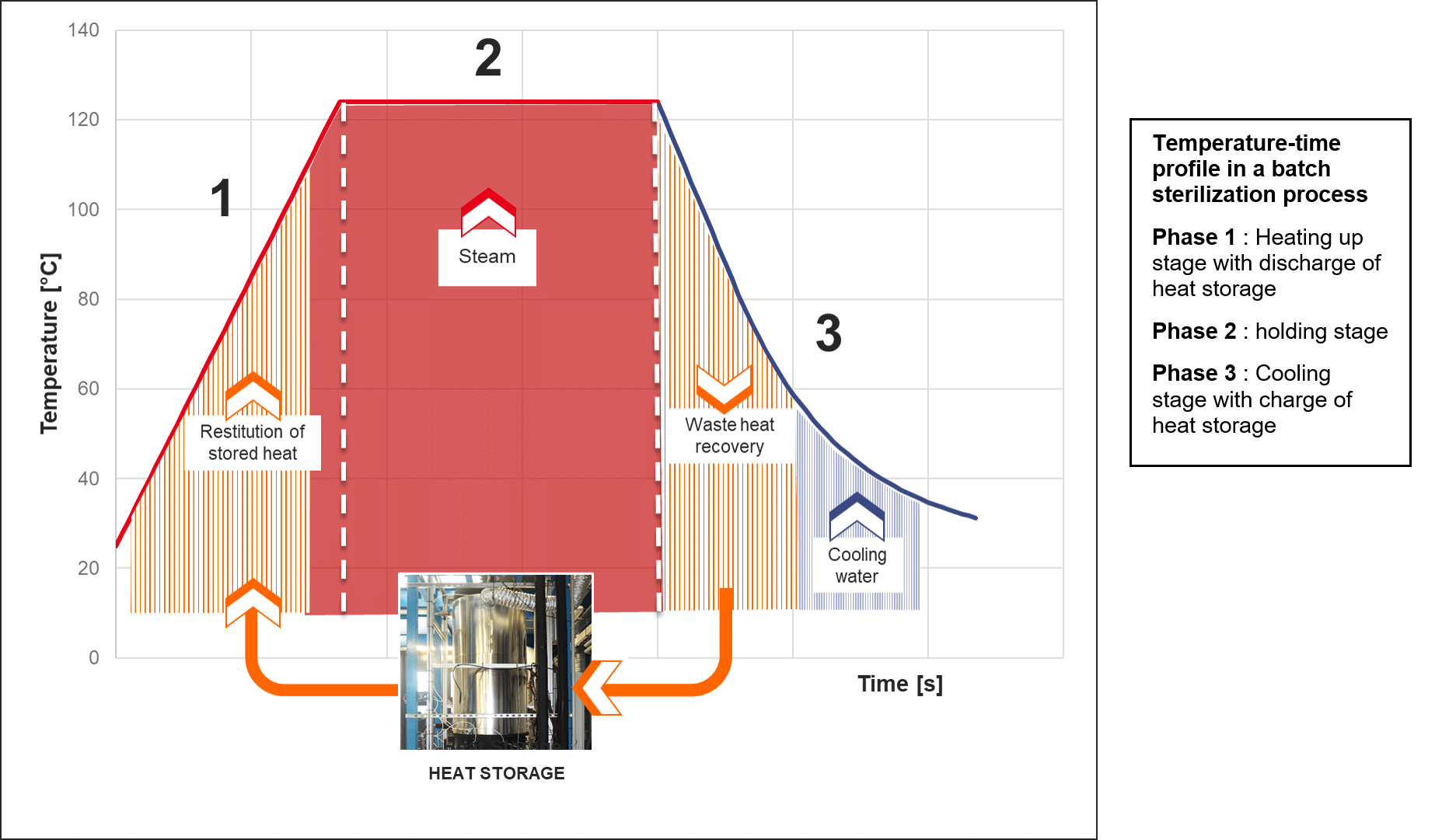

batch processes used in food manufacturing require a significant amount of energy to raise, maintain, and lower processing temperatures.

Recovering heat during cool-down is one solution. This heat can then be stored in a way that limits the degradation of available energy and injected directly into the same process during the next heat-up cycle. Lower process water consumption (either direct for steam or indirect, such as for wet cooling towers) is an added benefit.

|

Schematic diagram of the solution for recovering lost heat in a batch process

Waste heat recovery research aligns with CEA-Liten's core missions of decarbonizing the industrial sector and supporting manufacturing job creation. With several years of

experience in waste heat recovery research behind it, CEA-Liten continues to leverage know-how in thermal engineering originally developed for the nuclear industry and made available to public- and private-sector stakeholders over the past two decades. CEA-Liten is also home to

testing labs and a multidisciplinary team that can support R&D partners from design to deployment of innovative solutions, utilizing a full range of numerical modeling, laboratory characterization, and evaluation methods to achieve optimal technical, economic, and environmental parameters.

In research funded by French energy agency ADEME in 2020, CEA-Liten researchers

patented a compact, innovative waste heat recovery and storage solution for batch sterilization processes used in the food manufacturing and pharmaceutical industries. The solution connects to both steam and cooling water,

reducing the primary energy consumption (often gas) of these processes by

more than a third without impacting sterilization temperature ranges or otherwise altering the processing of the food.

Water consumption is also reduced, and the cold source is less sensitive to ambient temperature. A new project is currently being developed with a France-based equipment manufacturer in the agri-food and cosmetics sectors, among others, GOAVEC, with the goal of building industrial-scale demonstrator systems to prepare for future commercial deployment.

And the solution has applications beyond food manufacturing. A pharmaceutical industry partnership with heat treatment specialist ACTINI is underway in France's Haute-Savoie region, where waste heat is being recovered from pharmaceutical effluent batch decontamination processes, slashing both gas and water consumption by more than half and increasing production volumes and yields.

These two projects are wonderful examples of how waste heat recovery can help different industries improve energy efficiency and shrink their carbon footprints.