Researchers are currently focusing their efforts on two complementary strategies, to reduce the risk of thermal runaway. The first involves using more stable materials or safety devices to lower the probability of thermal runaway occurring, while the second strategy revolves around mitigating the impacts, thereby limiting propagation between cells in the battery's core. Both of these strategies will draw on many aspects, such as cell spacing and isolation, and the availability of a cooling system to prevent overheating.

In order to determine the scale of means designed to mitigate its impacts, CEA-Liten has explored the key factors contributing to the propagation of thermal runaway, including the amount of gas and overall energy released, heat flows, temperature, and pressure.

A transparent X-ray testing device that can withstand up to 400°C and 200 bars

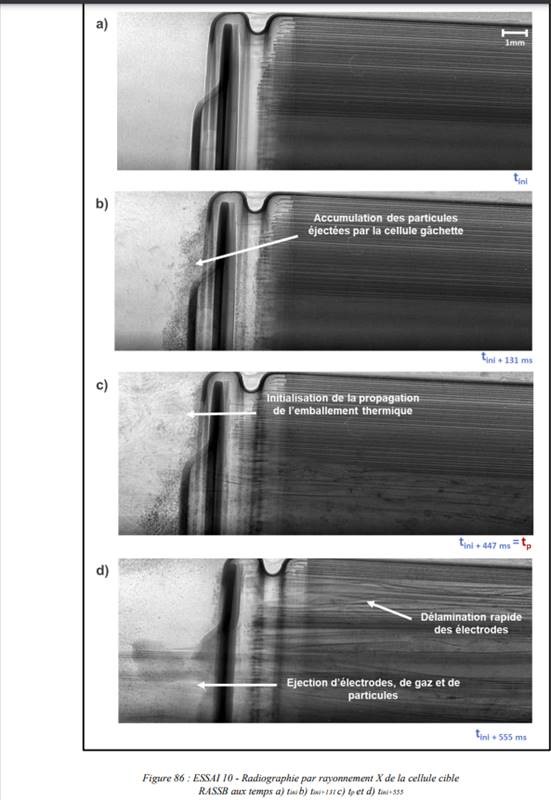

“To move things forward, we needed to generate and analyse some serious thermal runaway," said Natacha Darmet, the PhD student leading this thesis work. “We managed to do this in a closed and instrumented experimental device that is able to withstand temperatures of up to 400°C and 200 bars of pressure. This has allowed us to perform high-speed X-ray radiography at the ESRF [European Synchotron Radiation Facility], in order to observe the operando thermal runaway."

In this device, which is essentially a type of tube, two cells are positioned facing one another. Dubbed the “trigger", the first cell is overheated until thermal runaway occurs, which is then propagated to the target cell under study.

Tests were carried out using batteries with two different chemistries that are not commercially available: fully charged type 18650, third-generation, liquid-electrolyte cells (3 Ah LIB NMC811/GrSi); and LLZO-electrolyte, fourth-generation, all-solid-state cells collected using the same charged electrodes.

All-solid-state cells: ten-times bigger heat flow

“Our sensors measured several physical variables simultaneously. In addition, by comparing pressure monitoring and X-ray images, we were able to index the propagation process in real time with a view to testing the heat flow, and not only the energy released," explained Natacha Darmet.

This made it possible to explain the most striking research finding: the fact that each all-solid-state cell had enough energy to trigger the next, enabling the propagation of thermal runaway between these cells. “As it happens, the overall energy they release is similar to that released by third-generation cells. But the heat flow is ten-times bigger – 1828 kW rather than 176 kW – hence the five-times faster propagation."

Conversely, the fourth-generation cells studied release half as much gas as their third-generation counterparts during the thermal runaway process, and the strategies aimed at confining or releasing these gases with a view to preventing propagation could be easier to implement.

Other potential tests on future industrial-scale cells

These findings will be fed into ongoing collaborations with many manufacturers regarding the safety of their future all-solid-state batteries. “From now on, we will be trying to determine appropriate design parameters to prevent propagation. Thanks to our experimental device, we are also able to carry out tests combining excessive pressure and operando observation of all types of cells with several different energy storage capacities," said Natacha Darmet.

This thesis work has been published in:

N. Darmet, J. Charbonnel et al, ACS Applied Energy Materials Volume 7, Issue 10, Pages 4365 - 437527 May 2024