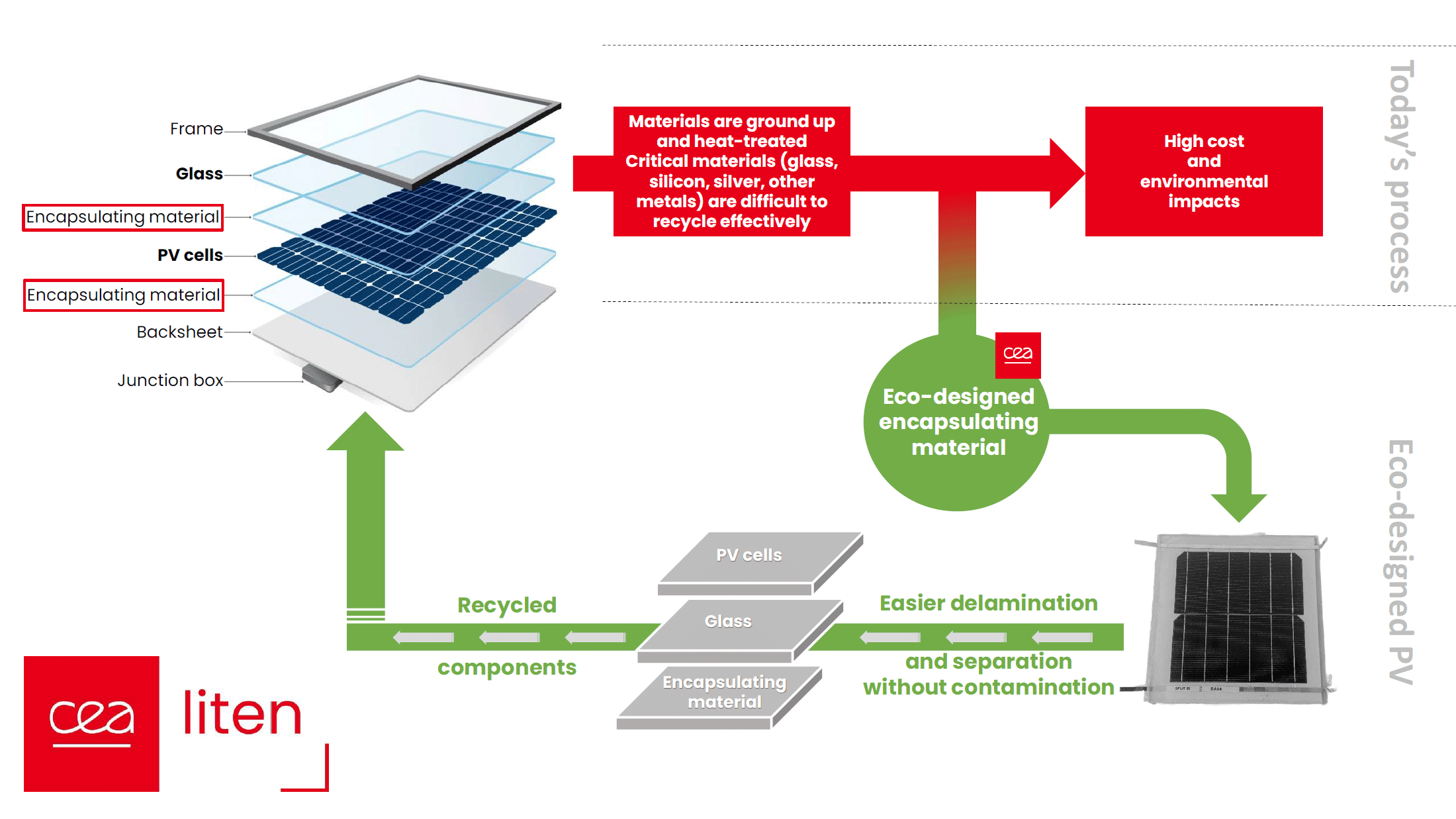

At CEA-Liten, we are committed to reducing the environmental impacts of energy production, including solar energy. Our researchers have come up with an innovative solution to enhance the separability of the layers that constitute PV modules so that the materials can be recovered more easily for recycling.

Key figures

Average lifespan of PV panels

~ 30 years

Estimated cumulative volume of panels to be recycled in 2050:

60 million tons

90% of the PV panels’ mass can be recovered today, but the processing steps are complex

| This improvement relies on the development of an alternative to the conventional thermoset materials used to encapsulate PV modules—one that would make separating the components easier without negatively affecting the optical and thermomechanical properties necessary for PV systems. Therefore, transparency was a major consideration. Our researchers were able to overcome this challenge using vitrimers*, a new kind of polymer, which they obtained using an innovative approach based on siloxane chemistry. The resulting completely transparent material established a new state of the art |

The novel transparent vitrimers were then successfully integrated into miniature PV modules. One of the other challenges—also overcome by this innovation—was maintaining robust adhesion between the glass and vitrimer. The PV modules were tested in a representative environment, and showed remarkable results with electrical performance close to that of reference modules and optical transmission approaching 90%. The glass, solar cells, encapsulation material, and backsheet were then effectively separated using thermal delamination. The purity of each component was preserved, a factor that is essential for the re-use of the materials recovered to manufacture new PV modules.

|

|

This successful proof of concept will lay the groundwork for further testing of the new encapsulation materials, with the goals of improving their formulation and developing a continuous synthesis process to manufacture them.

* A vitrimer is a thermoset polymer that can be processed like a thermoplastic (using covalent bond exchanges) and that exhibits thermoset-like durability, but with the recyclability of a thermoplastic.