The OSCAR software platform (reactor contamination simulation tool) models contamination and material transfers in nuclear reactor systems. It has been mainly developed within a collaborative framework with EDF and Framatome since the 1970s. It includes several applications:

- OSCAR-REP: Transfer of activated corrosion products, water activation products, fission products and actinides in the primary and auxiliary systems of PWRs.

- OSCAR-Na: Transfer of corrosion products into the primary sodium of SFRs.

- OSCAR-Fusion: Transfer of corrosion products into the water cooling systems of nuclear fusion reactors.

- OSCAR-PN: Transfer of corrosion products, fission products and actinides in the primary and bypass systems of naval nuclear propulsion reactors.

- OSCAR-Secondaire (under development): Transfer of corrosion products into the secondary system of PWRs (clogging/fouling).

- OSCAR-SMR and OSCAR-MSR (in project phase): Transfer of corrosion products, fission products and actinides into the primary and secondary systems of water-cooled SMRs and molten salt reactors (MSR).

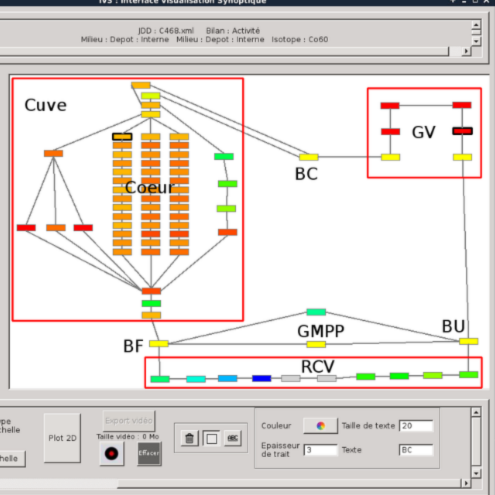

The modular nature of the code, developed in C++, means that mechanisms specific to each application can be implemented. The OSCAR calculation kernel is coupled with the PHREEQCEA chemistry code (ISAS/DPC) and the ALCYONE fuel code (IRESNE/DEC). A single code manages all of these applications, which can be used remotely (OSCAR service). User-friendly input and output interfaces developed on SALOME (ISAS/DM2S) are delivered to partners or customers to build datasets and process results (see screen shot below).

A host of transfer mechanisms are taken into account: corrosion of materials or release of fission products and actinides from leaking fuel, convection, purification, dissolution, precipitation, erosion, deposition, absorption, diffusion, activation, radioactive decay, etc.

The validation of OSCAR-REP is based on more than 420 gamma spectrometry measurement campaigns of surface activities in the primary systems of French and foreign reactors (EMECC campaigns), as well as on primary fluid filtration campaigns.

The OSCAR applications meet the industry’s needs in terms of the occupational dosimetry of personnel involved in reactor operation and maintenance, radioactive effluents and waste, reactor dismantling, reactor availability, and the source term in incident or accident conditions.