The nuclear fuel additive manufacturing workshop is located in a nuclear ICPE (Installation Classée pour l'Environnement), Labo UO2, operated by the Department of Fuel Studies within IRESNE.

Nuclear fuel elements are usually made by pressing uranium oxide powder. This process imposes constraints that limit the range of possibilities (geometry, constituents, etc.) for the materials to be manufactured.

The additive manufacturing technology chosen for the current studies is robocasting. It enables three-dimensional objects to be created from a digital model. Objects are created layer by layer by extruding a paste. Once printed, the parts are heat-treated to consolidate them and produce a dense material.

Robocasting also enables several materials to be processed simultaneously.

Using this printing technology, we can change shapes and materials at will, and, for example, create metal networks in UO2 ceramic. The result is a composite material known as CERMET for ceramic-metal.

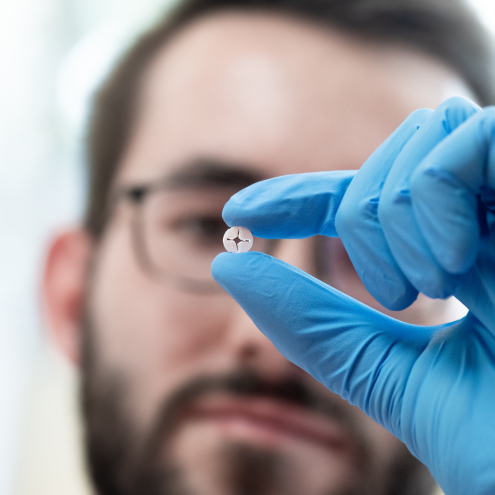

Since 2021, ceramic or CERMET pellets simulating nuclear fuel (uranium oxide, UO2) have been produced using this process, in alumina (aluminum oxide) or alumina/metal. They are prototypes for the development of more complex innovative fuel pellets.

The aim is to improve the thermal, mechanical, chemical and neutron properties of future fuels, and ultimately to test new concepts.

Additive manufacturing technologies have not yet been perfected for the production of uranium oxide fuel prototypes. This is the missing link in a fully digital design, from drawing to property modeling.

The development of the additive manufacturing workshop is being carried out in a collaborative framework with EdF and Framatome, and in collaboration with IRCER (Institut de Recherche sur les Céramiques). It involved the construction and development of a prototype printing machine. The transposition of this technology to the UO2 material is currently underway at the UO2 lab.